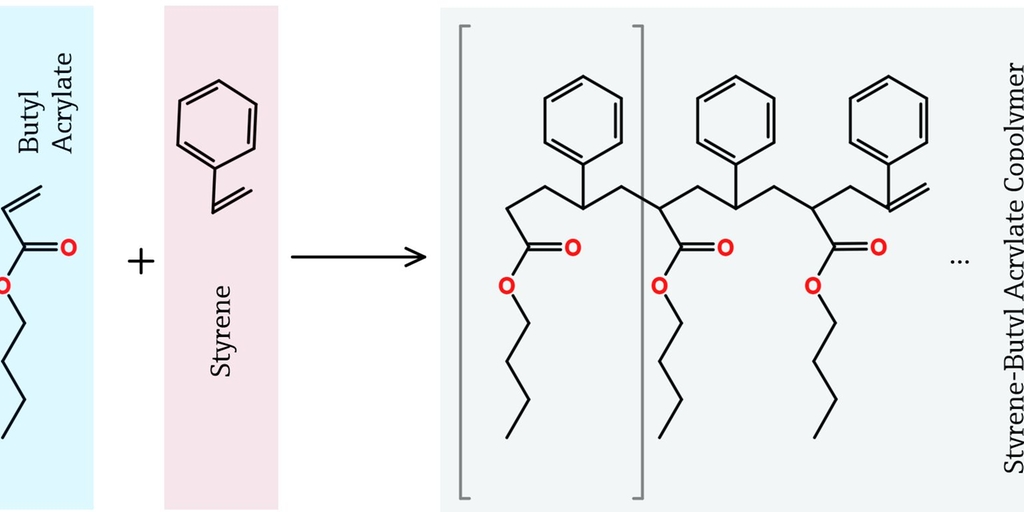

These include emulsion polymerization solution polymerization suspension polymerization and precipitation polymerization. Antara polectron 430 polymer is a white thermoplastic 38-41 percent solids latex produced as a graft emulsion copolymer of 30 percent polyvinylpyrrolidone and 70 percent styrene.

Particle Size Control In The Soap Free Emulsion Polymerization Of Styrene By An Oil Soluble Initiator With A Weakly Acidic Water Soluble Initiator Sciencedirect

Product is Polystyrene.

. Firstly the styrene is mixed with the surfactant sodium dodecyl sulfate solution forms a billions of emulsified micelles which are in uniform diameter. We have two types of polyethylenes and they are given below. ABS is the largest selling engineering thermoplastic worldwide.

It can be produced by free-radical emulsion polymerization of styrene and butadiene either at 50 to 60C hot emulsion SBR or at about 5C cold emulsion SBR. Structure and mechanical properties of Polystyrene-co-acrylatecellulose nanocrystals co-continuous composites via one-pot pickering emulsion polymerization Authors first second and last of 7 Yi He. Moreover it has significant advantages over bulk and solution polymerization processes.

As an optional adjuvant substance limited to no more than 2 weight percent based on polymer solids in the coating emulsion. Monomer a molecule of any of a class of compounds mostly organic that can react with other molecules to form very large molecules or polymers. It is a blend of all these three monomer units.

Then a little amount of potassium persulfate is added to it which is a water soluble. Mass and emulsion polymerization and mass suspension method are widely employed to produce grafted ABS. Triethylene glycol methacrylate for use only as polymerization cross-linking agent in side seam cements for.

The support polymer in aqueous ammonia solution acts as a. Preparation of Polymers Polyethene. The hot emulsion SBR process which was developed first leads to a more branched polymer than the cold emulsion process.

Acrylonitrile butadiene and styrene. Trinseos MAGNUM ABS Resins are manufactured with our proprietary continuous mass polymerization technology. Paints adhesives coatings varnishes etc Dubé et al 1997.

Emulsion polymerization is the procedure that is applied for the preparation of latex particles. Although the polymer polydispersity and. An example of Alkene Polymerization in which styrene monomers double bond reforms as a single bond plus a bond to another styrene monomer.

The reaction includes either monomer adsorption polymerization and emulsion polymerization. The most common type of emulsion polymerization is an oil-in-water emulsion in which droplets of monomer the oil are emulsified with surfactants in a continuous phase of water. Substrate of polybutadiene acrylonitrile styrene emulsion polymerization Substrate of polybutadiene acrylonitrile styrene mass polymerization 1 0 price 2 polymers-recyclables acrylonitrile-butadiene-styrene 1 2 206 Acrylonitrile Butadiene Styrene aka.

Bifunctional monomers can form only linear chainlike polymers but monomers of higher. Acrylonitrile Butadiene Styrene ABS is an opaque thermoplastic and amorphous polymer. Our mass ABS is purer cleaner and superior as compared to emulsion ABS since the continuous process results in a more consistent stable and reliable product.

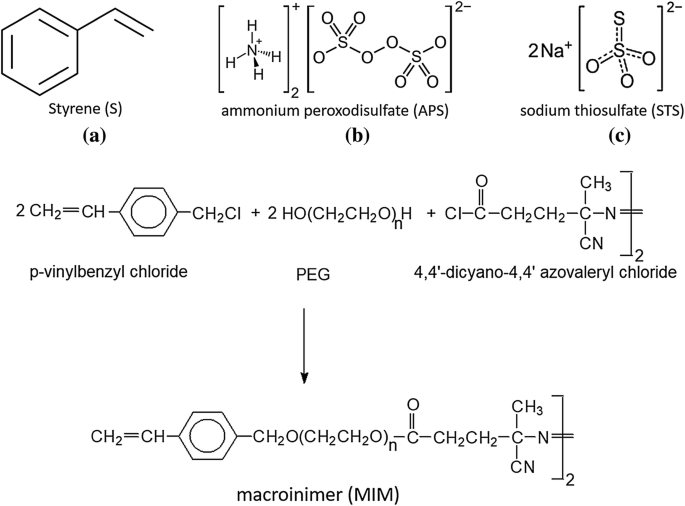

The reaction results in a polymer which is also soluble in the chosen solvent. Free radical emulsion polymerization is carried out at two different temperatures. Emulsion polymerization is a type of radical polymerization that usually starts with an emulsion incorporating water monomer and surfactant.

Solution polymerization is a method of industrial polymerizationIn this procedure a monomer is dissolved in a non-reactive solvent that contains a catalyst or initiator. A waterborne paint for traffic marking contains as an emulsion binder a support polymer formed of styrene and acrylic acid monomers and having an acid value of between about 50 and about 250 and a hydrophobic emulsion polymer comprised of acrylic ester monomers and optionally including styrene monomers. An illustration detailing the polymerization of the monomer styrene into the polymer known as polystyrene is provided below.

Moreover the viscosity of the reaction mixture. Heat released by the reaction is absorbed by the solvent and so the reaction rate is reduced. Emulsion polymerizations of styrene were performed in a one.

Thermoplastic as opposed to thermoset refers to the way the material responds to heat. Flame-retardant ABS are produced by addition flame retardant halogen-based organic. SBR grades produced using this process have exception.

Maleic anhydride adduct of butadiene styrene. Globally the most common methodology to create ABS is the emulsion. Butadiene and styrene copolymer blown or unblown.

The essential feature of a monomer is polyfunctionality the capacity to form chemical bonds to at least two other monomer molecules. In the hot process an initiator such as potassium peroxydisulfate is used and in the cold process a redox. Albeit less commonly by a patented process known as continuous mass polymerization.

It can be produced by solution and emulsion polymerization of styrene and butadiene. With a glass transition temperature of approximately 100C it forms transparent thermoplastic films that readily adhere to glass plastics and metals. 50C hot emulsion grade and 510C cold emulsion grade.

Emulsion polymerization is an important industrial process used to produce a great variety of polymers of multiple uses eg. ABS thermoplastic resins is composed of three kinds of monomers.

Understanding About Emulsion Polymerization Of Styrene Kompasiana Com

Monitoring Emulsion Polymerization Reactions Endress Hauser

Soap Free Emulsion Polymerization Of Styrene Using Poly Methacrylic Acid Macro Raft Agent Sciencedirect

Pdf Preparation Of Polystyrene Spheres Using Surfactant Free Emulsion Polymerization Semantic Scholar

Ii And Iii Illustrate Scheme Of The Emulsion Polymerization Download Scientific Diagram

Schematic Representation Of Emulsion Polymerization Of Styrene With Download Scientific Diagram

Particle Activation Deactivation Effect In Raft Emulsion Polymerization Of Styrene Reaction Chemistry Engineering Rsc Publishing Doi 10 1039 C6re00168h

Emulsion Polymerization An Overview Sciencedirect Topics

Kinetic Events Of Micro Emulsion Polymerization Of Styrene Springerlink

Two Step Sg1 Mediated Emulsion Polymerization Of N Butyl Acrylate Or Download Scientific Diagram

Emulsion Polymerization Of Styrene Under Continuous Microwave Irradiation Sciencedirect

Figure 1 Fabrication Of Polystyrene Detonation Nanographite Composite Microspheres With The Core Shell Structure Via Pickering Emulsion Polymerization

Scheme 4 Mechanisms Of The Polymerization Of Styrene In The Presence Download Scientific Diagram

009 Emulsion Polymerization Making Polymer Nanoparticles Youtube

Emulsion Polymerization Youtube

Preparation Of Transparent Polystyrene Nano Latexes By An Uv Induced Routine Emulsion Polymerization Sciencedirect

.jpg)

Using Kaiser S Ramanrxn2 Analyzer To Monitor Emulsion Polymerization Reactions